Superior Aluminum Foundry Solutions

Superior Aluminum Foundry Solutions

Aluminum CASTING

We can manufacture prototype parts with our in-house infrastructure from sand mold aluminum gravity casting, heat treatment to machining and measurement. Since we have heat treatment facilities in our foundry, we can provide heat treatment and quenching under customer-specified conditions as well as JIS standards.

heat treatment

Using an optical emission spectroscopy machine that can analyze multiple elements in the metal simultaneously with high accuracy, we inspect the material thoroughly for each casting furnace. We are also the first company in Japan to be accredited for the 'NVLAP Fasteners and Metals Program' (lab code:200536-0) in the field of emission spectroscopic analysis of AC4C, a JIS standard for aluminum alloy castings. (Casting Section, Head Office)

japanese Craftsmanship with Exceeding Expectations

Asanuma Giken has a full lineup of major CAD software, including CATIA V5, NX, Creo, etc., and can handle a variety of

native 2D and 3D data.

We can also modify CAD data such as slope and fillet, and provide material data upon request.

material data as you like

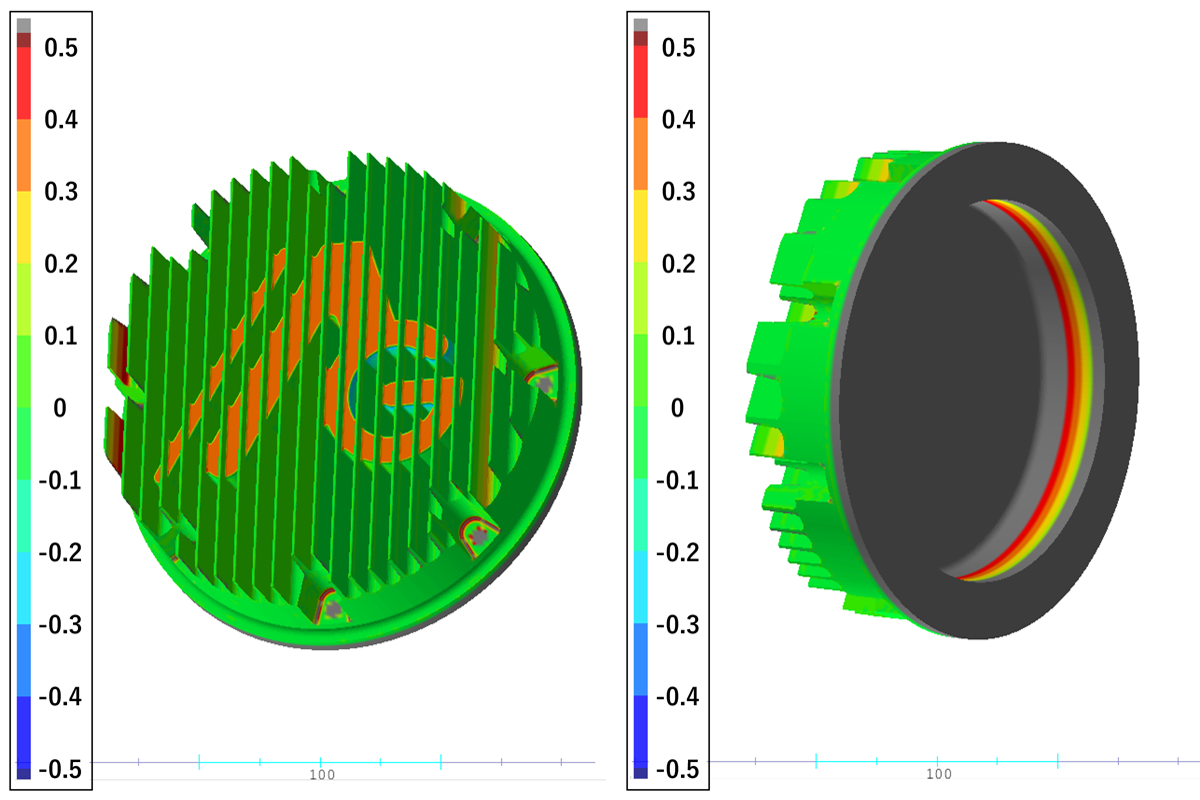

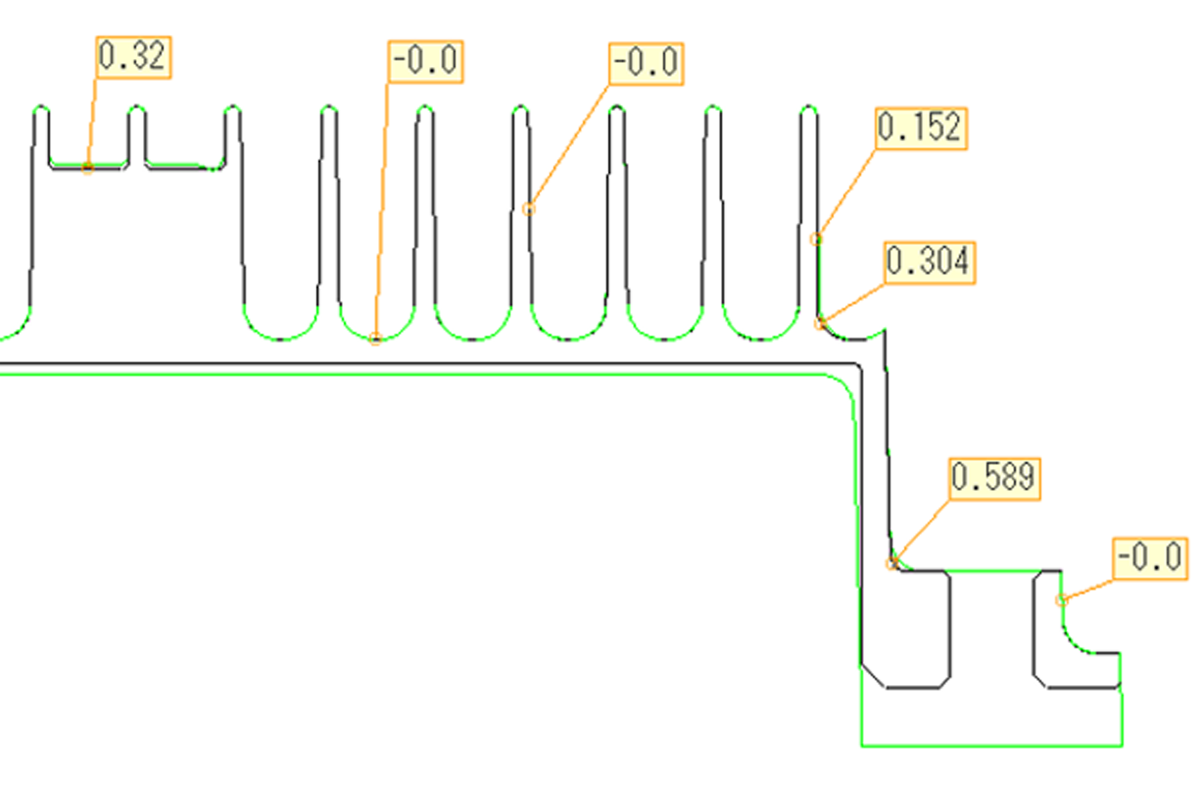

A camera-type non-contact measuring machine is used to inspect the external shape of castings. By superimposing the obtained point cloud data on the 3D data of the product, it is possible to accurately and quickly check the differences in the color map from the complex overall shape of the free-form surface to twists and tilts that are difficult to determine visually. We will provide the verification results as contour data in the form of a color map.

| Visual comparison with CAD | Detailed dimensional inspection by cross-sectional evaluation |

|

|